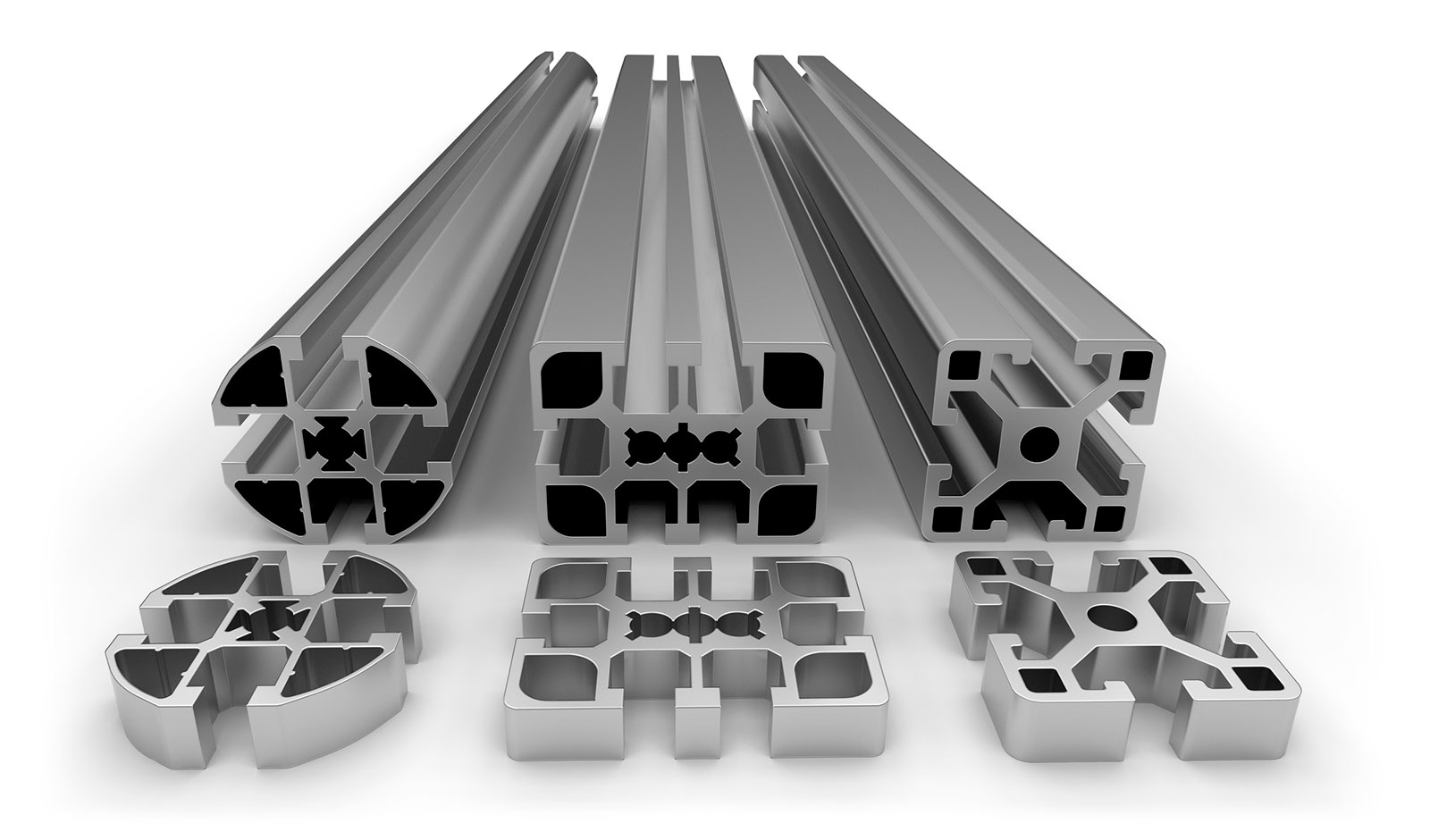

Алюминиевый профиль по чертежам заказчика

Максимальный диаметр описанной окружности профиля – 315 мм, применяемые сплавы – АД0, АД1, АД31, АД35 (AW6082), AW6060, AW6063 в требуемом клиентом состоянии поставки (проведение необходимых режимов термообработки). Максимальная масса погонного метра профиля – 21 кг., стандартная длина хлыста – 6 м.

ЭТАПЫ ИЗГОТОВЛЕНИЯ ПРОФИЛЯ

1. Составление технического задания и оптимизация.

Этот этап включает в себя разработку чертежей с одновременной оптимизацией основных параметров профиля.

При составлении технического задания наши конструкторы подготовят всю техническую документацию и сделают необходимые расчеты, оптимизировав конфигурацию профиля по параметрам цены и качества.

2. Расчет стоимости матричного инструмента и профиля.

После утверждения чертежа и согласования цены, заказчик оплачивает матричный инструмент (Фильера). Стоимость фильеры зависит от конфигурации и начинается 1000$. Средний срок ее изготовления составляет от 30 до 40 дней.

При единовременном заказе от 10 тонн профиля одной конфигурации, матричный инструмент изготавливается бесплатно.3. Изготовление опытных образцов.

В течение 5-10 дней после изготовления матрицы заказчик получает опытный образец, для проверки на соответствие всем требованиям. Стоимость производства опытных образцов включена в стоимость изготовления и настройки матричного инструмента.

4. Изготовление основной партии алюминиевого профиля.

После утверждения заказчиком опытных образцов мы приступаем к изготовлению основной партии профиля. Этот процесс называется экструзия и занимает порядка 10 дней. В работу принимаются заказы от 500 кг.

В процессе производства профиль ООО «БАЙКАЛЬСКИЕ ПРОФИЛЬНЫЕ СИСТЕМЫ» подвергается термической обработке, повышающей его прочностные характеристики (закалка, искусственное старение).

5. Последний этап – электрохимическое анодирование профиля или его окрас.

По желанию заказчика мы проводим покраску в любой цвет или анодирование партии готового профиля в течение 14 дней с момента производства.